Over 100 years ago.

Over 100 years in the making, Laxtons has grown from a turn of the century entrepreneurial mill to one of the world’s most respected yarn manufacturers. Here’s a whistle stop tour of how we became the business we are today.

Where it all began.

In 1907 George Laxton and Gordon Holmes formed a worsted spinning mill Holmes Laxton & Co in Oakworth, combining George Laxton’s technical know-how and Gordon Holmes’ financial expertise producing wool and mohair yarns. Prior to the First World War, together with a local Bradford weaver, they developed a new technology which dissolved away cotton fibre leaving pure mohair thus creating the first light weight mohair suiting fabric in the world.

Threadbare Thirties.

Around the depression of the 1930’s, Holmes Laxton were forced into a one-week-on, one-week-off arrangement which lasted for around three years. During this time, the Company started to export its yarns to Germany for the manufacture of upholstery fabrics. Business began to improve but was then hit again by the Second World War. George Laxton’s son, who was also called George and had joined the Company in 1930, signed up as a volunteer in the Royal Air Force.

The Fighting Forties.

During World War Two, the Company found its workforce decimated as the town’s men clamoured to sign up. The firm, however, continued to operate producing yarns for military uniforms under the guidance of the Wool Control government body based in Yorkshire and throughout the war women took over the work traditionally carried out by the men. After the war, George Laxton was the first UK yarn salesman to go back to Germany to visit his old customers, of which only one remained of the original 35 prior to the war, the majority having been destroyed in bombing raids. Business was slow to recover as the Germans rebuilt but in time growth in the sector started to be seen.

Swinging Sixties.

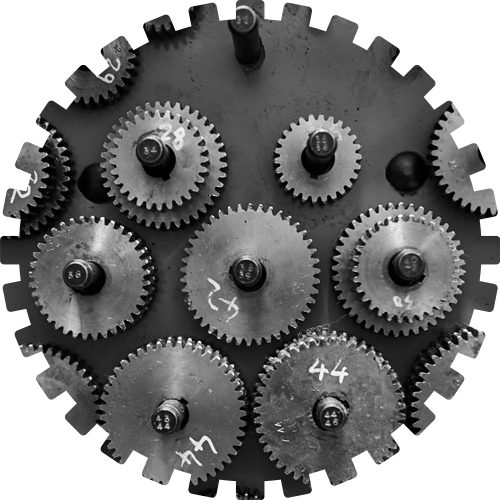

Following a slow recovery after the war, the Company started to grow once again. George Laxton passed away in 1956 leaving two generations of Laxtons on board; George Laxton junior and John Laxton (George Laxton junior’s son). In the early 60’s the Company exported 99% of its production. The Company started to replace its old machinery and invest in its future growth transferring all the machinery to Prospect Mills in Ingrow, whilst expanding at the same time. The yarns were adapted from upholstery to ladies outerwear and then supplied to weavers in Huddersfield, Scotland and to a variety of overseas markets.

Super Seventies.

By now Ian Crawford had joined the Company, following Gordon Holmes retirement in 1966. In 1974 they purchased a mohair fancy twisting plant in Scotland and began producing yarns for hand knitting. The Company soon outgrew their home in Ingrow and built a new state of the art facility in Silsden. The new site quickly grew into one of the most modern, successful plants in the UK and Europe manufacturing mohair fancy yarns and blends, selling both in the UK and to over 80 countries worldwide.

Naughty Nineties.

In the late 80’s/early 90’s we set up a joint venture with a co-operative of mohair farmers in South Africa where we relocated an entire spinning plant from Yorkshire to Port Elizabeth. James Laxton, the fourth generation, joined the company in 1992 to be faced with probably the most devastating 10 years in the history of the UK’s textile industry. With a combination of cheap imports and customers starting to move off shore, trade became very challenging with hundreds of textile spinning companies closing their doors permanently.

Laxtons today.

After re-shoring 100% of our manufacturing in December 2009, we have managed to invest in additional manufacturing capacity over the previous seven years. As a result, we outgrew our old premises and have built a state-of-the-art new spinning mill not only increasing our capacity with new machinery but also our capability in being able to offer an even more diverse range of yarns for many different markets and end uses. We recently moved into our new premises and are looking forward to showcasing what is possible in our new factory.